Yerba Mate Article

From the fields to your gourd: How Yerba Mate is Grown and Produced

Yerba Mate has been cultivated for hundreds of years, and more recently the production has been commercialised. Here is more information on the process by which yerba is grown, harvested and the processes involved to turn it from a growing plant, to the dried tea leaves we know and love.

Growing Process

Yerba mate is a tea made from the ground leaves and stems of the Ilex Paraguariensis, a small shrub like tree that grows up to 15 metres with white flowers and small red fruit that are berry-like. Yerba mate is mainly grown in South America, particularly in Northern Argentina, Paraguay, Uruguay and Southern Brazil. It grows best in subtropical jungle climates.

Plantations vary from small plots to vast areas, and planting may be by hand or by agricultural machinery. Organic yerba is grown without the use of chemicals, and as such the crops are usually smaller and higher quality, more natural in taste.

Harvest

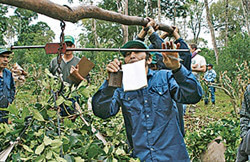

If harvested by machine, it is allowed to grow to around 7-8m only. The best quality yerba is harvested by hand – there is reduced wilting, withering or fermenting of the leaves. Workers who harvest by hand traditionally cut the leaves and stems with knives and carry the harvest in white sheets folded ontheir backs.

Processing (dried, cured, milled and packaged)

Firstly the yerbamate is dried. It is passed on conveyor belt through a wood-fired kiln and quick scorched. Approx 20% of the moisture is removed at this stage. Still on the conveyor the yerba passes into a more moderate, indirect heat for up to 8 hours. Organic yerba is dried completely naturally. At the end of this stage all remaining moisture is removed so the leaves will not rot, ferment or lose nutrition.

The end taste of the yerba can be influenced at both stages of the drying process.Where fire is used, the type of wood can be changed to give different flavour.The yerba can be exposed directly to the fire, or can be indirectly exposed and a smoking process occurs. The combination of length of time or each method can subtly affect the taste

The yerba is then pre-milled into pieces of about 1cm and stored in open weave sacks to cure. During this time any gases leave the yerba, and most importantly, the flavour matures and develops. The finest yerba is left to cure for a period of 2 years.

The next step is milling. The dried yerba is now milled to the relevant size and quality for its end use. In this way it is possible to differentiate blends that all come from the same crop:

- The stems can be removed for a stronger blend

- The yerba can be ground very finely for teabags, or very coarsely for Paraguayan yerba and Terere

- The finest quality leaves can be sold as ‘pick of the crop’ or ‘special blend’ and the very fine ‘dust’ particles can be removed

- The medium quality (majority of the yerba) is sold as the brands’ standard blends

- The lower quality yerba that is left is sold off cheaply and packaged by cheaper brands

The yerba then may be sold loose to be resold in markets, but the majority of commercially-grown yerba is packaged and branded. Most consumption of yerbamate is in southern South America, however there is a growing demand across the world.